- Rubber Processing Machinery[7]

- Waste Management[10]

- Other Recycling Products[8]

- Rubber Product Making Machinery[1]

- Other Energy Related Products[5]

- Plastic Processing Service[1]

- Paper Processing Machinery[1]

- Other Electrical Equipment[1]

- Energy Saving Equipment[1]

- Reactors[2]

- Other Machinery[5]

- Other Environmental Products[9]

- Recycled Rubber[2]

- Gasoline[3]

- Other Plastic Processing Machinery[1]

- Plastic Recycling Machinery[5]

- Boilers[7]

- Rubber Processing Service[1]

- Other Metallurgy Machinery[1]

- Contact Person : Mr. jiang Eric

- Company Name : Henan Guangming Steel Structure Engineering Co., Ltd.

- Tel : 86-370-3167908

- Fax : 86-370-3167908

- Address : Henan,Shangqiu city,Chenfeng road, Economic and Development zone, Shangqiu city, Henan province

- Country/Region : China

- Zip : 470063

waste rubber recycling machinery

The Four Models:

According to the different capacity of the machines, it has been divided into four models: GM-5100. GM-6000, GM-2600-6000, GM-2800-6000.We named all of the machines as GM-6000 series equipment in this instuction. And this instruction is applicable to every model.

And the four models has several differences:

Item | Content | |||

Equipment model | GM-5100 | GM-6000 | GM-2600-6000 | GM-2800-6000 |

Raw material | Plastic/rubber | Plastic/rubber | Plastic/rubber | Plastic/rubber |

Per batch productivity | 4 tons | 5 tons | 8 tons | 10 tons |

The device host material | Q245R boiler plate | Q245R boiler plate | Q245R boiler plate | Q245R boiler plate |

Thickness | 12mm/14mm | 12mm/14mm | 12mm/14mm/16mm | 12mm/14mm/16mm |

Work pressure | Normal pressure | Normal pressure | Normal pressure | Normal pressure |

Total electric power | 10kw | 10kw | 10kw | 10kw |

Cooling way | Water-cooling | Water-cooling | Water-cooling | Water-cooling |

Driving pattern | Gear driving | Gear driving | Gear driving | Gear driving |

Heating pattern | Direct or indirect | Direct or indirect | Direct or indirect | Direct or indirect |

Noise dB(A) | ≤85 | ≤85 | ≤85 | ≤85 |

Host size(L*W) | 2200*5100 | 2200*6000 | 2600*6000 | 2800*6000 |

Working pattern | Intermittent/continous | Intermittent/continous | Intermittent/continous | Intermittent/continous |

Delivery time | 15-25 days | 15-25 days | 15-25 days | 15-25 days |

The GM-6000 series equipment is the national patent enviromental protection product. Advanced to the "technical, technological, excellent device configuration, the tight control of the production process" constitutes a quality assurance Henan Guangming the strong backing. It costs the least resoure in the whole process. This is also our patent techniques. We adopt the unique horizental rotary structure, the advanced automatical slag-out system. Besides this, we provide the best all-around after-sale service.

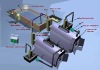

The Dedusting system:

Dedusting system

Note:

1. The main machine, the device host

2 . The connecting pipe, 219mm diameter

3. The deduster 4. Water tank 5. The water pump, 1.5kw

6. The connecting pipe, 50mm diameter 7. Spray thrower

8. The connecting pipe, 325mm diameter 9. The draught fan, 4kw

10. The chimney, 325mm diameter

When heating 1) the device host with fuel such as coal or firewood, a lot of smoke from the hearth will come through 2) the connecting pipe to 3) the deduster. Finally, before discharging the smoke, it is clean, no smell, no pollution.

First, the smoke comes into the deduster to be cooled. Then the draught fan delivers the cooled smoke to the atomization system in a desulfurization tower which is 3m high and 1m diameter (the water in the tower is supplied by the water pump ). In the tower, the smoke first meets Pall rings, a layer of porcelain buffer, then meets the water vapor from the high pressure nozzle on the top, and last there is a layer of wire netting to stop the water vapor coming out of the tower. So in the process of coming through the tower, almost all of the dust and sulfer are stopped. Finally, there is little water vapor comes into the vapor and goes out from the chimney. And we can also put some chemical into the water to remove the sulfer again according to the requirements. This whole set of dedusting system has been certified to meet the demands of Korean enviromental protection requirements.

Environmental Protective

Dispose waste gas, liquid, and residua in the process:

1. Waste gas: Transferred through two safety device: water close &burning air nozzle. Fully burnt, not only eliminated pollutant but also minimized the quantity of fuels. For smoke dust discharge, we apply series machines of patent in our company Desulphurization and dust remover which could control the smoke dust discharge amount meet relative standards of GB-2001.

2. Waste liquid: Produced waste acidic water in the process of oil disposing (50kg process from 1 ton of oil easy to process for small quantity). counteract the liquid by alkalescent liquid solution. After three stage of filtration, the litmusless waste water was introduced to evaporator(use the heat of the flue of main processor as its heating resource)

3. Waste solid. The solid residua will be left after the catalyst splitting from scrap plastic, approximately composes the waste plastic weight about 5% to 10%. Its main component is the thick black carbon. It can be the raw material of the production industry of black carbon. Also could be mixed with the pulverized coal ash which produces for the raw material thermal power plant, also could be the raw material of manufacture pulverized coal ash brick (one kind of environmental protection building material).

waste rubber recycling machinery